water hose splitter stl 3d print:

The world of 3D printing has unlocked endless possibilities for creating functional and customizable tools, from household gadgets to complex engineering components. One practical item that can easily be designed and printed is a water hose splitter. Whether you need to direct water to multiple garden areas or split a hose for various uses, a 3D-printed splitter offers versatility, cost-effectiveness, and the ability to customize your setup.

In this comprehensive guide, we will walk you through the process of designing and printing a water hose splitter STL file for 3D printing. We’ll also explore the advantages of creating your own splitter and provide tips for selecting materials and ensuring a successful print.

Why 3D Print a Water Hose Splitter?

Water hose splitters are common garden tools that allow you to divide a single water source into two or more directions. Traditional splitters are often made from metal or plastic, but by 3D printing your own, you gain the advantage of customization and personalization. Here’s why 3D printing a water hose splitter is a great option:

- Customization: You can design the splitter to fit any specific needs, whether it’s altering the size, the number of connections, or even the angle of the split.

- Cost-Effective: 3D printing can reduce costs by eliminating the need for mass-manufactured components. You can design and print exactly what you need, saving money on specialized parts.

- Sustainability: By printing only what you need, you reduce waste and can select environmentally friendly materials like PLA (polylactic acid), which is biodegradable.

- Quick Prototyping: If you need to make design changes or improvements, 3D printing allows you to iterate quickly.

How to Design a Water Hose Splitter STL for 3D Printing

Before you start printing, you need a 3D model of the water hose splitter. STL (Stereolithography) is the most commonly used file format for 3D printing, representing the surface geometry of a 3D object without any color or texture. There are two primary ways to get a water hose splitter STL file:

1. Download an Existing STL File

There are several websites like Thingiverse or MyMiniFactory that offer free or paid STL files. If you’re new to 3D printing or don’t want to design a hose splitter from scratch, this is the simplest option. However, these pre-made models might not meet your specific needs in terms of size or functionality.

2. Design Your Own STL File

For more advanced users, creating a custom design allows for greater flexibility. Popular design software like Tinkercad, Fusion 360, or FreeCAD lets you model the splitter according to your exact specifications. Here are a few tips for designing an effective water hose splitter:

- Accurate Measurements: Ensure that the dimensions match the size of your water hoses. For example, standard garden hoses typically use a ¾-inch connection.

- Threaded Connectors: If you want your splitter to screw directly onto a hose, make sure to design threaded ends.

- Durability: Keep the walls thick enough to handle water pressure, typically around 2-3 mm for PLA or PETG prints.

- Water Flow: Design the internal channels to minimize water flow restrictions and prevent leaks.

Selecting the Right Material for 3D Printing

Once you have your STL file ready, the next step is to choose the right material for your 3D print. Since the splitter will be exposed to water, sunlight, and possibly high pressure, choosing the right filament is crucial. Here’s a breakdown of the best materials for 3D printing a water hose splitter:

- PLA (Polylactic Acid): PLA is a popular choice due to its ease of printing and biodegradability. However, it’s not the best material for outdoor use as it degrades under UV light and can soften with high temperatures.

- PETG (Polyethylene Terephthalate Glycol): PETG is highly recommended for outdoor use because of its strength, water resistance, and durability. It’s also less prone to warping than PLA.

- ABS (Acrylonitrile Butadiene Styrene): ABS is another durable option for outdoor applications. It has good mechanical properties but is harder to print due to warping issues.

- TPU (Thermoplastic Polyurethane): TPU is a flexible filament that can withstand stress and pressure, making it a great option for water hoses that may experience high force.

Printing the Water Hose Splitter: Best Practices

To ensure a high-quality print for your water hose splitter, follow these best practices:

1. Layer Height and Infill

- Use a layer height of 0.2 mm or lower for smoother surfaces and better thread definition.

- Opt for at least 30% infill to maintain strength, particularly in the walls and connectors.

2. Support Structures

- Depending on your design, you may need to print with supports to ensure the overhanging threads or internal channels print correctly. Use breakaway supports to make post-processing easier.

3. Test Fitting

- Before printing the entire splitter, print a small section of the threaded connector to ensure it fits your hose. This can save filament and time if adjustments are needed.

4. Post-Processing

- After printing, remove supports and sand the threads or connector areas to ensure a smooth fit with your hose.

Troubleshooting Common 3D Printing Issues

While 3D printing a water hose splitter is a relatively straightforward process, there are a few common issues you may encounter:

- Leakage: If your splitter leaks, check the walls of your print to ensure they’re thick enough, or try printing with a higher infill percentage.

- Threading Issues: If the threads don’t fit properly or are too loose, adjust the model dimensions in your design software and reprint a test piece.

- Warping: For materials like ABS that are prone to warping, use a heated print bed and consider adding a brim or raft to improve bed adhesion.

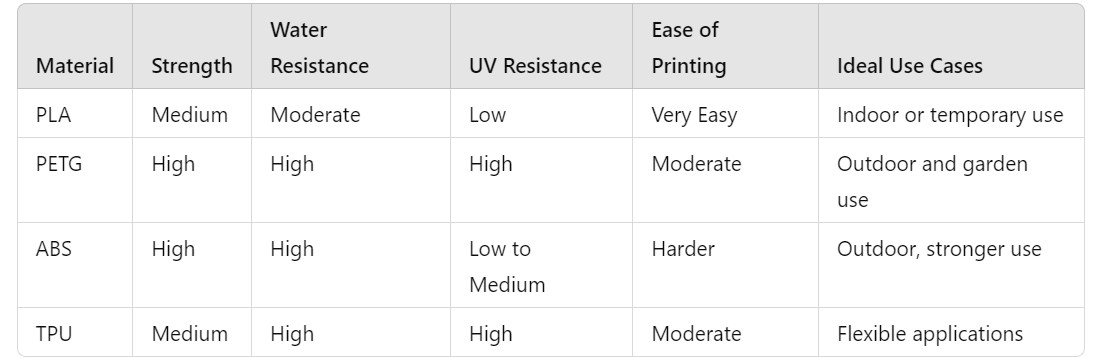

Table: Comparison of 3D Printing Materials for Water Hose Splitter

Description: This table compares different filament materials for 3D printing a water hose splitter, including factors like strength, water resistance, and UV resistance. PETG is generally the best choice for outdoor use.

Conclusion: Customizing and Printing Your Own Water Hose Splitter

3D printing a water hose splitter from an STL file offers many benefits, including customization, cost savings, and environmental sustainability. Whether you’re downloading a pre-made STL file or designing your own, selecting the right material and following best printing practices ensures a durable and functional tool. With 3D printing, you can tailor your splitter to your exact needs and improve the convenience of your garden watering system.

FAQs

1. Can I 3D print a water hose splitter for outdoor use?

Yes, but make sure to use durable materials like PETG or ABS that are resistant to water and UV light.

2. What is the best material for 3D printing a water hose splitter?

PETG is recommended for outdoor use because of its water resistance and UV stability.

3. How thick should the walls of the splitter be for water pressure?

Aim for a wall thickness of around 2-3 mm to handle typical garden hose pressure.

4. Do I need to use supports when printing a water hose splitter?

Yes, especially for threaded sections or complex internal designs. Supports ensure the print quality of overhanging parts.

5. Can I customize the size of the splitter to fit different hoses?

Absolutely. By designing your own STL file, you can adjust the size to fit any hose connection.

6. How can I ensure my 3D-printed splitter doesn’t leak?

Use a high infill percentage (30% or more) and make sure the threads fit tightly to prevent leaks.