Setting the timing on an Accucraft Ruby steam locomotive is essential for optimal performance and efficiency. This guide will walk you through the process step-by-step, ensuring you understand each aspect of timing, as well as common adjustments and troubleshooting methods. Whether you’re a novice or a seasoned enthusiast, this guide will help you make the most of your Accucraft Ruby model.

What Is Timing, and Why Is It Important?

In a steam locomotive like the Accucraft Ruby, timing refers to the precise alignment of the steam valves with the movement of the pistons. Proper timing ensures that steam enters and exits the cylinders at the right moments, which maximizes power and efficiency. Incorrect timing can lead to poor performance, overheating, and even potential damage.

Key Benefits of Proper Timing:

- Improved Efficiency: Steam usage is optimized, reducing fuel and water consumption.

- Increased Speed: Proper timing allows for smooth, continuous motion.

- Reduced Wear: Correct timing reduces mechanical stress and prolongs locomotive life.

Tools Needed for Timing an Accucraft Ruby

Before beginning, gather these essential tools and materials:

- Small screwdrivers (Phillips and flathead)

- Hex key or Allen wrench (for removing and adjusting components)

- Feeler gauge (optional, for precise gap measurements)

- Ruler or calipers

- Flashlight or LED lamp (for visibility inside small components)

Step-By-Step Guide: How to Set the Timing on an Accucraft Ruby

Follow these steps carefully to set the timing accurately.

Step 1: Access the Timing Mechanism

- Remove the Body Shell: Start by gently unscrewing and removing the body shell to expose the internal components. Keep screws in a safe place to avoid losing them.

- Locate the Valve Gear: Identify the valve gear components, particularly the eccentric crank and the timing rods. These parts are critical for adjusting timing.

Step 2: Set the Eccentric Crank

The eccentric crank controls the position of the valve as the wheel rotates, determining when steam enters and exits the cylinder.

- Align the Piston: Rotate the driving wheels to move the piston to its furthest forward position.

- Position the Eccentric Crank: The crank should be slightly behind the vertical position. Adjust it by loosening the set screw and rotating the crank if necessary.

- Test Alignment: After setting the crank, rotate the wheels slowly and check that the valve opens and closes in sync with the piston’s movement.

Step 3: Adjust the Valve Rod Length

- Check the Rod Length: Measure the length of the valve rod between its connection points. On most Rubies, the correct length is around 24-25 mm.

- Adjust the Rod if Needed: If the rod is too long or too short, use a hex key to loosen the adjustment screw and extend or shorten the rod. A longer rod delays valve opening, while a shorter rod advances it.

Step 4: Fine-Tune Using Trial and Error

Now, test the setup to ensure the timing is correct:

- Rotate the Wheels Manually: Turn the driving wheels manually through several full rotations. Listen and feel for any rough spots or hesitations.

- Make Small Adjustments: If the timing is off, make minor adjustments to the eccentric crank and valve rod length. Repeat this process until the wheels turn smoothly and without resistance.

Step 5: Reassemble and Test the Locomotive

Once the timing feels correct:

- Reassemble the Body Shell: Secure the body shell and ensure that no screws are loose.

- Test Under Power: Place the Ruby on a track and run it slowly under steam. Observe the motion and listen for any misfires or rough running. Minor adjustments may still be necessary to achieve ideal timing.

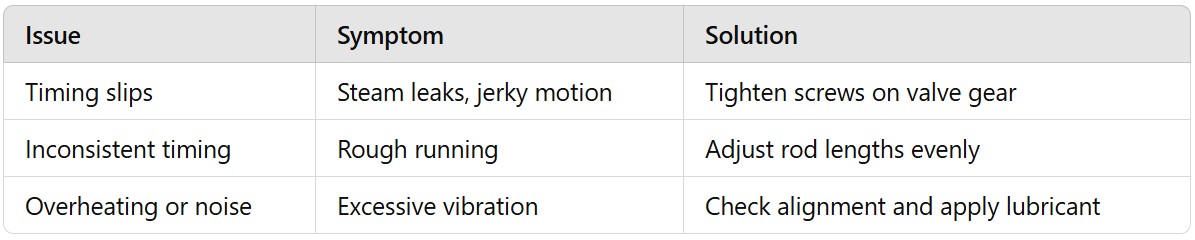

Common Issues and Troubleshooting

Timing Slips After Operation

- Solution: Check that all screws and connections on the valve gear are secure. Loose components can lead to slipping.

Inconsistent Valve Timing

- Solution: This may result from uneven rod lengths. Measure and adjust each rod to ensure they’re consistent.

Overheating or Excessive Noise

- Solution: If the locomotive overheats or makes unusual noises, check for over-tightened screws or misaligned components. Lubricate moving parts if necessary.

Performance Chart for Accucraft Ruby Timing

Tips for Effective Timing on an Accucraft Ruby

- Work in a Clean Area: Small parts can easily be lost, so work in a tidy, organized space.

- Use a Flashlight: Lighting up small components makes alignment and adjustments easier.

- Take Notes: Document each adjustment to track what works and avoid repeating mistakes.

Expert Opinions on Accucraft Ruby Timing

Many model locomotive enthusiasts agree that precise timing is one of the best ways to improve performance on the Accucraft Ruby. According to steam model expert Martin Fielding, “Proper timing is crucial for getting the smoothest ride and longest lifespan out of your Ruby locomotive.” This consensus highlights the importance of paying close attention to timing for optimal operation.

Transitioning to Advanced Timing Adjustments

Once you are comfortable with basic timing, advanced adjustments—like setting for increased speed or power—can further enhance performance. Experimenting with minor timing variations can help you better understand how your model behaves under different settings.

FAQs: how to set the timing on a accucraft ruby

Q1: How often should I adjust the timing?

A: Regularly check every six months, or sooner if performance declines.

Q2: What’s the most common sign of timing issues?

A: Rough or jerky movement and excessive noise are common indicators.

Q3: Can I use regular machine oil for lubrication?

A: Yes, but avoid thick oils, as they can impede smooth operation.

Q4: Is a feeler gauge necessary?

A: While not essential, it’s helpful for precise gap measurements.

Q5: What should I do if the locomotive overheats?

A: Check for over-tightened screws or misaligned parts, and lubricate as needed.

Q6: How can I test timing without running steam?

A: Manually turn the wheels and listen for smooth engagement.

how to set the timing on a accucraft ruby: conclusion

Setting the timing on an Accucraft Ruby locomotive might seem challenging, but with patience and attention to detail, it’s manageable for any hobbyist. Following this guide will help you achieve optimal timing, leading to smoother, more efficient performance. Remember, adjustments may take time, but the results are well worth the effort. By regularly checking and adjusting the timing, you can enjoy a reliable and powerful Accucraft Ruby locomotive for years to come.